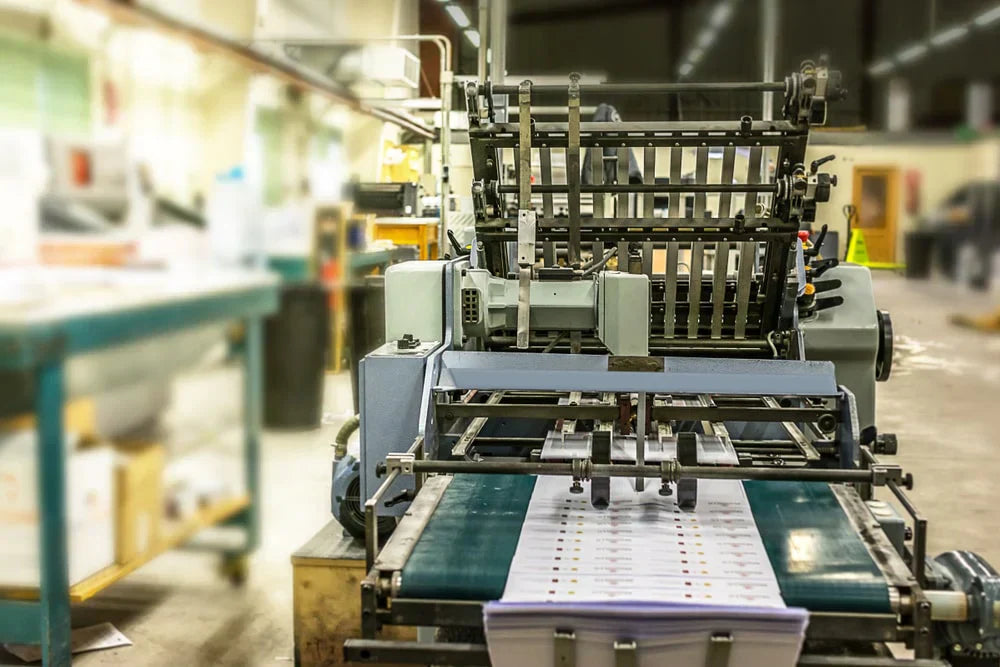

What are Creasing Machines?

A creasing machine is used to crease, score, and perforate paper and cards for easy folding. Its purpose is to speed up the folding process and create a uniform, professional-looking finish. Industries such as printing, packaging, and publishing utilize paper-creasing machines.

The device may have manual or automatic operation. In both instances, paper is fed between two plates or rollers, and is folded or scored. You can easily make adjustments to customize manual and electric creasing machines for materials of various sizes and thicknesses. Advanced creasing machines have digital displays and programmable settings, making them incredibly precise.

What are Creasing Machines used for?

Creasing machines are used to create a fold or crease in assorted paper and card materials. Here we will share some examples of where this may be applied in various industries. We’ll discuss the differences between manual creasing machines and automatic creasing machines, and how these differences impact their use.

Example Applications

Electric creasing machines are important tools in the printing industry. They help printers create professional-looking brochures, leaflets, magazines, and similar branding or marketing materials.

In postage and packaging, a paper creasing machine is used to fold letters neatly, and score packaging and cartons. A creasing machine may also be used to help bind books, produce greeting cards, and make office stationery. If you opt for a creasing machine with a perforator, you can also create materials that require a tear-off, such as invitations, coupons, and tickets.

Manual vs. Automatic

Creasing machines fall into two main categories, manual and automatic. Users must pull a lever, or rotate a handle, to operate a manual creasing machine. This makes them more suitable for little organizations or businesses that use a creasing machine on a smaller scale, such as for postage within a non-industrial setting.

Automatic creasing machines require little effort from the user. An air feed creasing machine, for instance, uses air and suction to pull in materials. It can produce thousands of creases per hour. Therefore, they’re naturally more fitted to larger-scale operations in industries like digital printing.

It’s also worth noting that different creasing machines have distinct capabilities. For instance, a friction feed creasing machine that works with rollers to pull in the materials is only compatible with standard paper because of the level of grip. However, an air-feed creasing machine can handle both standard and glossy paper.

Benefits of Creasing Machines

Efficiency - Professionals can streamline their processes with a manual or automatic creasing machine, without sacrificing quality. If you have a busy production line, this is particularly important. By saving time, you also save on labor and expenses.

Versatility - These days, you can purchase multi-functional creasing machines that process papers and cards of different sizes and thicknesses. This allows you to serve the unique needs of all your clients. The appearance of creases and perforations can be customized to suit specific requirements.

Professional Appearance - It’s highly unlikely you would be able to make such professional, clean-looking folds by hand. In business, it’s critical that promotional materials and packaging look sleek and sharp. When the promotional materials and packaging don’t have a professional appearance, it affects a brand’s image. They can indicate a lack of care and poor quality of products or services.

Does My Business Need a Creasing Machine?

You may be wondering if a creasing machine is worth the investment, or if you should update your existing machine to a new model. The truth is you can’t put a price on great first impressions or high-quality products. For these reasons and more, a creasing machine is worth the investment.

Make a Positive First Impression

Clients expect high-quality products. You may not realize the significance of a clean fold on a brochure or leaflet. In fact, the recipient may not notice it at all. But, they will definitely pay attention if the fold is misaligned, or if the paper is messy or cracked. Similarly, if a product arrives in a box that’s poorly folded, it gives a terrible impression.

Get the Presentation Right

It’s not worth wasting your hard work, or the hard work of your clients. A lot of time goes into designing promotional materials and crafting the perfect letter. You don’t want to detract from promotional materials and letters with poor presentation. A creasing machine will help you construct the perfect presentation.

Get a Return on Your Investment

From smaller, manual creasing machines, to advanced, automatic creasing machines, there are many options for businesses large and small. Also, there are creasing machines for a range of budgets. Purchasing these machines will pay off. In fact, even a manual creasing machine can speed up operations. In contrast, electric versions produce tens of thousands of creases per hour.

This means you increase productivity, and therefore your bottom line. Furthermore, when you automate processes with creasing machines, your staff is free to handle other tasks.

Expand Your Services

As you have seen, paper-creasing machines can be used in several ways. Invest in a multifunctional creasing machine for your printing business. For example, you can design invitations, tickets, and other materials with tear-offs for your clients, which will increase profits.

Creasing Machine FAQs

How does a creasing machine work?

When you fold paper materials by hand, the fibers tend to break. This may result in cracking or a messy finish. A paper creasing machine uses rollers or plates to compress the fibers, and form a clean U shape in the paper.

What is the difference between a score and crease?

Both actions prepare a sheet of paper or card for a clean, folded edge. Creasing provides a more pronounced indent in the material and reduces the likelihood of the paper cracking. Scoring offers a quicker process and may be done at the same time as applying other finishes. Moreover, the overall result may not be as clean as creasing.

What are the different types of creases?

Different creases may be used depending on the material you want to fold. Paper materials with a thickness of less than 0.10” use male/female creasing. Moreover, a crush crease may be used on paper thicker than 0.10”. In addition, a cut crease is used for durable materials that retain their memory.

If you have any further questions about creasing machines and the creasing process, feel free to contact us.

Conclusion

Paper creasing machines are increasingly in demand thanks to their rich benefits to organizations of all sizes. At Whitaker Brothers, we have a number of creasing machines appropriate for a variety of budgets. If you run a small operation or are just starting out, take a look at the Martin Yale SP100 Score and Perf Machine. Alternatively, if you’re looking for high-capacity, multi-functional equipment for your printing business, discover the Formax Atlas-TRIO15 Slitter/Cutter/Creaser.