Cumberland 814X Beside-The-Press (800X Series) Granulator (Discontinued)

- SKU: NDS814X

This product has limited availability and/or is build-to-order.

Please call us at (800) 243-9226 or fill out the Request a Quote form, below.

Request A Quote

Need Advice?

Call us at (800) 243-9226

Call us at (800) 243-9226

| Manufacturer Name | Cumberland |

|---|---|

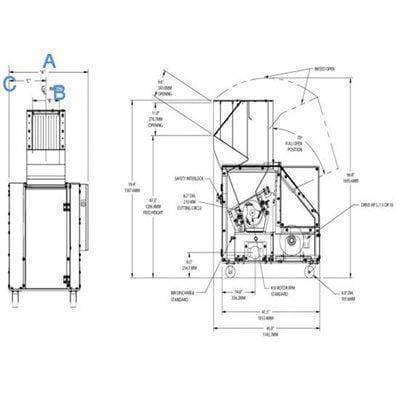

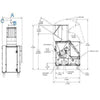

| Max Throughput | 172 lbs/hr (78 kg/hr) |

| Cutting Chamber | 8” x 14” (203mm x 356mm) |

| Rotor | 3-knife open-scooped with rotating end discs |

| Rotor Knives | 3 (HCHC) |

| Base | Full machine sound enclosure with casters |

| Discharge | Manual bin standard |

| Model # | 814X |

| Weight | 1400 lbs (635kg) |

| Height | 59.4" (1507mm) |

| Width | 34.3" (871mm) |

| Depth | 45.0" (1144mm) |

| Shipping Weight | 1400.0 lbs. |

QUESTIONS & ANSWERS

Have a Question?

Be the first to ask a question about this.